Jäteveden ilmastuskäsittelyn osuus on noin 60 % jätevedenpuhdistamojen kokonaisenergiantarpeesta. Energiankulutus on jätevedenkäsittelyn suurin kustannustekijä, ja sen optimointi on yksi monista haasteista, joita jätevedenpuhdistamon käyttäjät kohtaavat samalla, kun turvallisuuslainsäädännöstä tulee yhä vaativampaa. Hapen ja ravinneaineiden online-mittausratkaisut auttavat säästämään energiaa ilmastuksen säädössä, minkä lisäksi biologisissa prosesseissa on niiden ansiosta voitu todentaa merkittäviä parannuksia.

Olennaiset tiedot

Jopa 30 %

energiakustannuksista

voidaan säästää jätevedenpuhdistamoissa käyttämällä jatkuvaa ilmastuksen ohjausratkaisuamme.

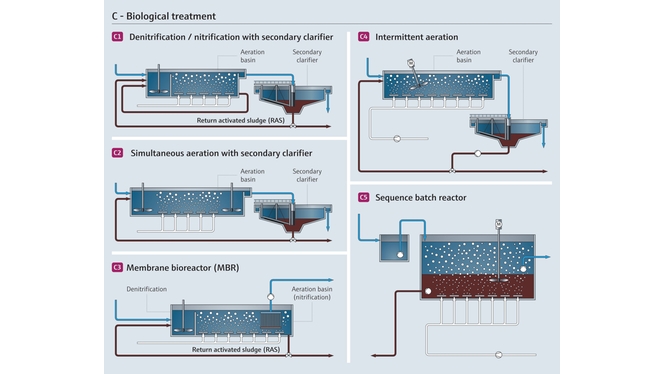

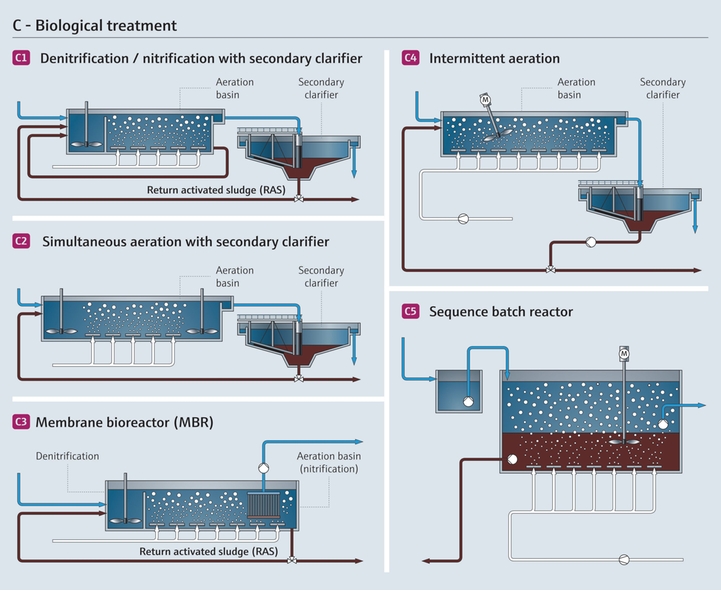

Tutustu jätevedenkäsittelyn ilmastusprosessiin

Yksinkertaistettu ilmastuksen valvonta

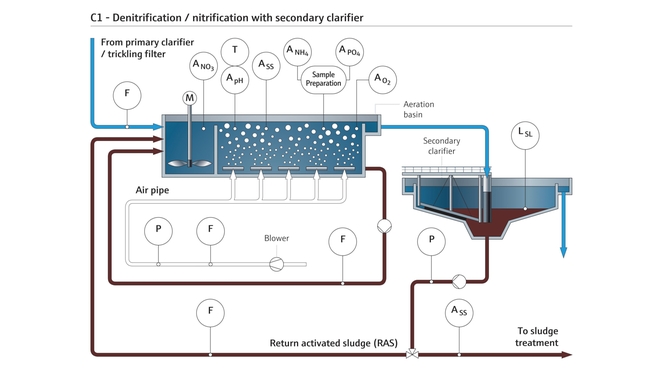

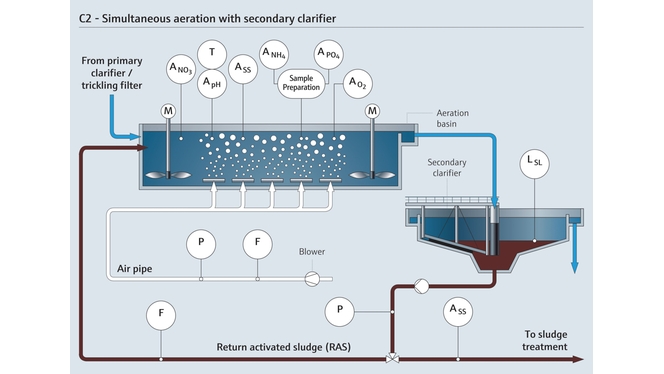

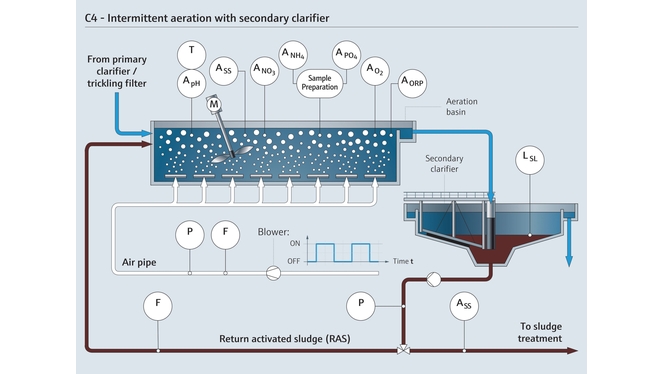

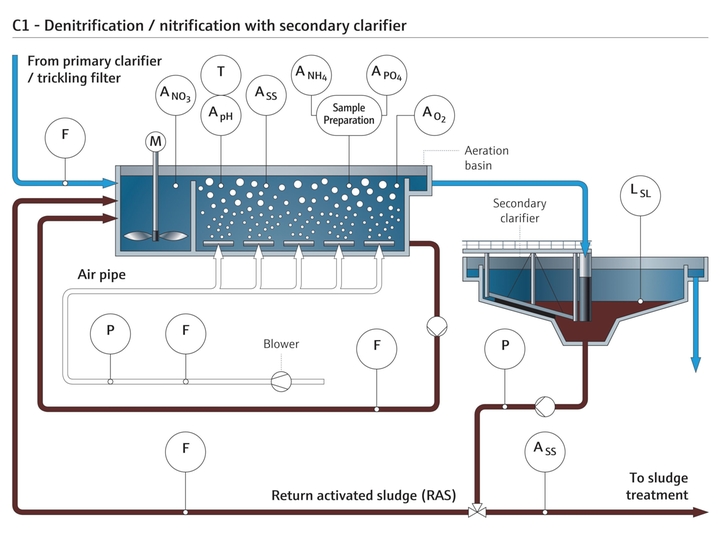

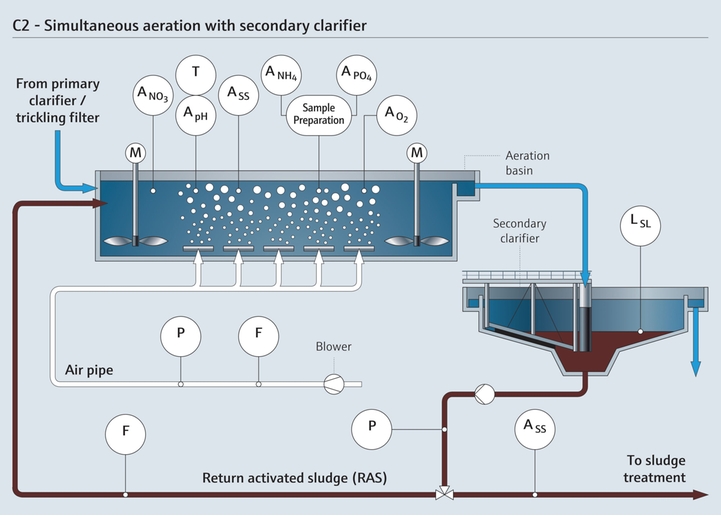

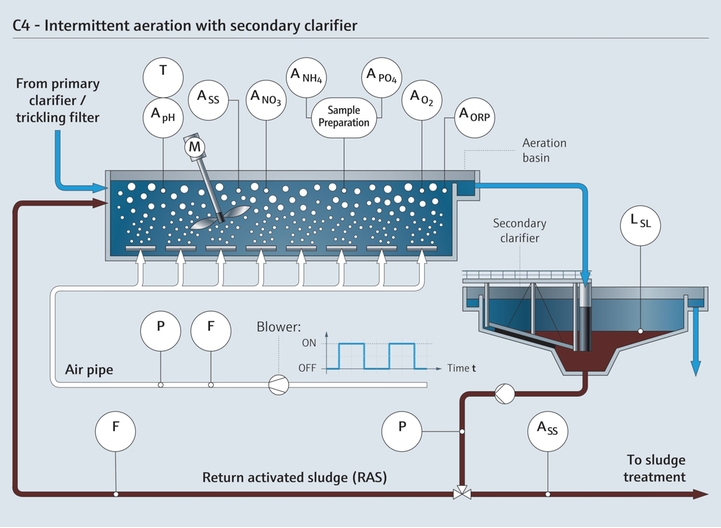

Luotettava ilmastus edellyttää monien ympäristöparametrien tarkkaa valvontaa, esimerkkeinä happi, ammonium, nitraatti, pH, lämpötila ja kiintoainepitoisuudet. Nämä mittaukset tarvitaan optimaalisiin tuloksiin pääsemiseksi bakteriologisissa prosesseissa. Tällainen valvonta lisää suuresti modernin jätevedenpuhdistamon hallinnan mutkikkuutta.

Alan asiantuntemuksemme

Kattava mittalaitteiden, palvelujen ja ratkaisujen valikoimamme auttaa optimoimaan ilmastusprosessit ja varmistaa laitoksen luotettavan ja tehokkaan hallinnan.

- Tutustu kaikki tärkeät parametrit kattavien analyysimittausanturiemme valikoimaan

- Tutustu lähemmin lämpötilan mittauksen lämpötilamittareihin ja lähettimiin

- Jopa kahdeksan samanlaisin tai erilaisin parametrein varustetun mittauspisteen hallinta monikanavaisella lähettimellä Liquiline CM448. Avoimet tiedonsiirtoliitännät ylläpitävät järjestelmäintegraatiota ja helpottavat toimintaa, kunnossapitoa ja kalibrointia

- Typen poistaminen jätevedestä turvallisesti Liquiline Controlilla

Pienemmät ammoniumtasot

Ensimmäinen vaihe typen poistamisessa on nitrifikaatio. Se vaatii tarkkaa ammoniumpelkistyksen valvontaa, mikä on merkittävä kustannustekijä, koska tällainen nesteanalyysi edellyttää usein muiden aineiden integrointia mittausten mahdollistamiseksi.

Alan asiantuntemuksemme

Luotettavat, helppokäyttöiset ja kestävät teknologiamme ammoniumpitoisuuden mittaamiseen koko nitrifikaatioprosessin ajan antavat käyttäjälle mahdollisuuden reagoida jo varhaisessa vaiheessa ammoniummäärien häiriöihin.

- Luotettavien anturien, kuten digitaalisten ammonium- ja nitraattianturien Memosens ISEmax CAS40D, integrointi käsittelyn optimointiin

- Voit luottaa erittäin tarkkaan ammoniumin mittaukseen kaikissa kriittisissä mittauspisteissä Liquiline System CA80AM -lähetinjärjestelmien ansiosta

- Edelleen optimoidut elinkaarikustannukset, koska käsittelyprosessin kunnossapito- ja varaosatarve ovat pienemmät

Joustava ja tarkka hapen valvonta

Luotettavan ilmastusprosessin kannalta elintärkeä happitasojen valvonta ja oikeiden tasojen ylläpito voivat aiheuttaa jätevedenpuhdistamolle merkittäviä energiakustannuksia. Puhdistamojen käyttäjät voivat luottaa nopeisiin vasteaikoihin ja laitteiston vähäiseen kunnossapitotarpeeseen.

Alan asiantuntemuksemme

Happitasoja säädetään vertaamalla mitattuja pitoisuuksia ja asetuspistettä. Hapen valvontaratkaisumme voidaan sopeuttaa joustavasti juuri sinun vaatimuksiisi, ja saat luotettavat ja tarkat tulokset nopeasti.

- Mittaa liuenneen hapen pitoisuus tarkasti digitaalisella amperometrisellä happianturilla COS51E

- Paranna prosessiturvallisuutta digitaalisen Memosens 2.0 -teknologian antureilla

- Vähentynyt energiankulutus puhaltimen käytön optimoinnilla

Edut

Yhdessä lukuisten asiakkaiden kanssa työskennellen alan ja sovelluksen asiantuntijamme ovat saavuttaneet erinomaisia tuloksia ilmastuksen optimoinnilla jätevedenpuhdistamoissa. Endress+Hauserin koko tuotevalikoima sisältäen mittalaitteet, palvelut ja ratkaisut varmistaa menestyksesi heti alusta alkaen. Tavoitteemme on olla luotettava kumppani jätevedenkäsittelyn jokaisella osa-alueella.

Olennaiset tiedot

Jopa 30%

energiakustannuksista voidaan säästää käyttämällä ilmastuksenohjausratkaisuamme

Olennaiset tiedot

40%

pidempi käyttöikä analyysimittausten antureilla, joissa on Memosens-teknologia

Olennaiset tiedot

300 000

Memosens-anturia asennettu ympäri maailman

Miten voimme auttaa

Edistyneiden valvontaratkaisujemme avulla ilmastusprosessin säätö sujuu optimaalisesti ja energian ja kemikaalien kulutusta voidaan vähentää samalla, kun voimassa olevan lainsäädännön vaatimusten toteutuminen varmistetaan.

- Ympäristöparametrien edistynyt valvonta varmistaa luotettavat bakteriologiset prosessit

- Parantunut nitrifikaatioprosessin hallinta vähentää ammoniumin käyttöä

- Tarkka happimittaus varmistaa puhaltimen optimaalisen energiankulutuksen