Tärkeimmät tekniset tiedot

-

Max. measurement error

±0.25 % o.r. ± 1 to 4 m/s (3.3 to 13 ft/s)

±0.5 % o.r. ± 1 mm/s (0.04 in/s)

±5 % o.r. -

Measuring range

0.14 to 1.66 l/s (0.035 to 0.44 gal/s)

-

Medium temperature range

Seal material EPDM: –20 to +130 °C (–4 to +266 °F)

Seal material Silicone: –20 to +130 °C (–4 to +266 °F)

Seal material Viton: 0 to +150 °C (+32 to +302 °F) -

Max. process pressure

PN 16

-

Wetted materials

Liner: PFA

Electrodes: 1.4435 (316L); Alloy C22, 2.4602 (UNS N06022), Tantalum,

Platinum

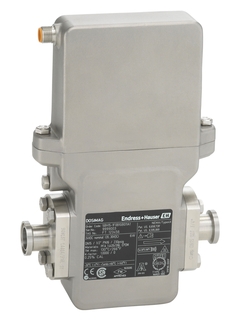

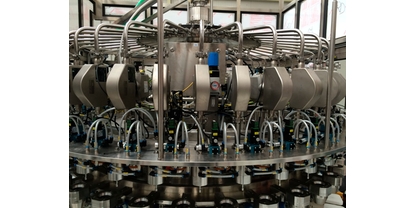

Käyttöalue

Dosimag is specially designed for filling and bottling applications of conductive liquids. It measures volume directly. Designed for applications where space is a premium, Dosimag will be the preferred choice for system integrators, skid builders and equipment manufacturers.

The bidirectional measuring principle is virtually independent of pressure, density, temperature and viscosity

For demanding dosing and filling applications.

Device properties

Wetted materials CIP, SIP cleanable

Nominal diameter: DN 4 to 25 (1/8 to 1")

Measuring device conform to FDA

Pulse/frequency/switch output, Modbus RS485

Custody transfer approvals (MID, NTEP)

Excellent and easy cleanable transmitter

Edut

High process safety – high measuring accuracy and repeatability in shortest filling time

Energy-saving flow measurement – no pressure loss due to cross-section constriction

Maintenance-free – no moving parts

Versatile and time-saving wiring – plug connector

Industry-optimized – ultra-compact design

For hygiene requirements – stainless steel housing

Videot

Xpert-valikoima

-

Erikoistuotteet

- Suunniteltu vaativiin sovelluksiin

Tekninen suorituskyky

Helppokäyttöisyys

Tuotekohtainen

-

Helppokäyttöiset tuotteet

- Helppoja valita, asentaa ja käyttää

Tekninen suorituskyky

Helppokäyttöisyys

-

Standardituotteet

- Luotettavat, lujatekoiset ja helppoja huoltaa

Tekninen suorituskyky

Helppokäyttöisyys

-

Laadukkaat tuotteet

- Erinomainen toiminnallisuus

Tekninen suorituskyky

Helppokäyttöisyys

-

Erikoistuotteet

- Suunniteltu vaativiin sovelluksiin

Tekninen suorituskyky

Helppokäyttöisyys

Tuotekohtainen

| FLEX-valikoima | Tekninen suorituskyky | Helppokäyttöisyys |

|---|---|---|

Fundamental-valikoima Täytä perusmittaustarpeesi |

Tekninen suorituskyky

|

Helppokäyttöisyys

|

Lean-valikoima Käsittele ydinprosessejasi helposti |

Tekninen suorituskyky

|

Helppokäyttöisyys

|

Extended-valikoima Optimoi prosessisi innovatiivisilla teknologioilla |

Tekninen suorituskyky

|

Helppokäyttöisyys

|

Xpert-valikoima Hallitse haastavimmatkin sovelluksesi |

Tekninen suorituskyky

|

Helppokäyttöisyys

Tuotekohtainen |

Loading alternative products

Loading alternative products

Edeltäjä

-

-

Tekniset tiedot (TI)

Dosimag Technical Information

Electromagnetic flowmeter

Flowmeter with maximum repeatability and ultra-compact sensor with

hygienic designEN FI 01/02/201701/09/201513/08/201401/11/2005Kieli:

Englanti

Versio:

01/02/2017

Tiedoston koko:

1.6 MB

Tiedoston nimi:

TI00066DEN_1517.pdf

-

-

-

Käyttöohje (BA)

Dosimag Operating Instructions

Electromagnetic flowmeter

EN FI 01/02/201701/09/201513/08/201415/05/2006Kieli:

Englanti

Versio:

01/02/2017

Tiedoston koko:

1.4 MB

Tiedoston nimi:

BA00098DEN_1517.pdf

-

-

-

Käyttöohje (BA)

Dosimag Modbus RS485 Operating Instructions

Electromagnetic flowmeter

EN FI 01/02/201701/09/201513/08/2014Kieli:

Englanti

Versio:

01/02/2017

Tiedoston koko:

1.5 MB

Tiedoston nimi:

BA01321DEN_0317.pdf

-

-

-

Laiteparametri (GP)

Dosimag Description of Device Parameters

Electromagnetic flowmeter

EN FI 01/09/2015Kieli:

Englanti

Versio:

01/09/2015

Tiedoston koko:

526.3 KB

Tiedoston nimi:

GP01049DEN_0115.pdf

-

-

-

Laiteparametri (GP)

Dosimag Modbus RS485 Description of Device Parameters

Electromagnetic flowmeter

EN FI 01/09/2015Kieli:

Englanti

Versio:

01/09/2015

Tiedoston koko:

701.6 KB

Tiedoston nimi:

GP01048DEN_0115.pdf

-

-

-

Lyhyt ohje (KA)

Dosimag Brief Operating Instructions

Electromagnetic flowmeter

EN FI 01/02/201701/07/201601/04/201601/09/201513/08/2014Kieli:

Englanti

Versio:

01/02/2017

Tiedoston koko:

1.1 MB

Tiedoston nimi:

KA01175DEN_0517.pdf

-

-

-

Asennusohjeet (EA)

Adapter RSE8, RSE5, RSE4 Installation Instructions

Proline Dosimass, Dosimag

EN FI 01/10/201814/04/2014Kieli:

Englanti

Versio:

01/10/2018

Tiedoston koko:

297 KB

Tiedoston nimi:

EA01104DA2_0218.pdf

-

-

-

Asennusohjeet (EA)

Exchanging electronics module and gasket Installation Instructions

Dosimag 5BH

EN FI 01/04/201901/01/2006Kieli:

Englanti

Versio:

01/04/2019

Tiedoston koko:

275 KB

Tiedoston nimi:

EA00041DA2_0219.pdf

-

-

-

Ex-turvallisuusohje (XA)

Dosimag ATEX: II3G Ex nA IIC T5 to T1 Gc IECEx: Zone 2 Ex nA IIC T5 to T1 Gc Safety Instructions

Documentation for hazardous areas

EN FI 01/02/201702/03/201601/09/201514/08/2014Kieli:

Englanti

Versio:

01/02/2017

Tiedoston koko:

321.4 KB

Tiedoston nimi:

XA01332DEN_0417.pdf

-

-

-

Erikoisasiakirjat (SD)

Dosimag Custody transfer Special Documentation

Electromagnetic flowmeter

EN FI 14/12/2015Kieli:

Englanti

Versio:

14/12/2015

Tiedoston koko:

171.3 KB

Tiedoston nimi:

SD01514DEN_0115.pdf

-

%20-%20CS01637X.jpg)

.jpg)