Avoid raw material and energy loss in your clean-in-place (CIP) process

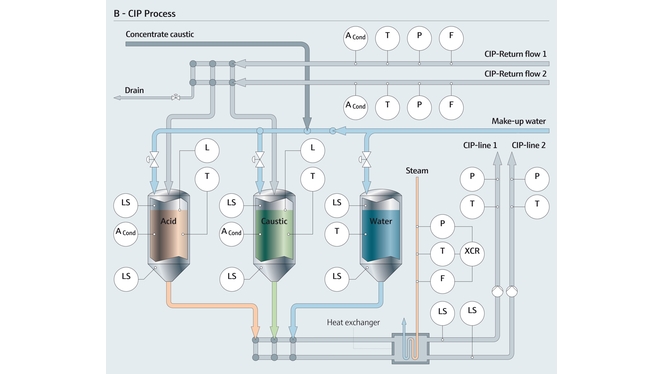

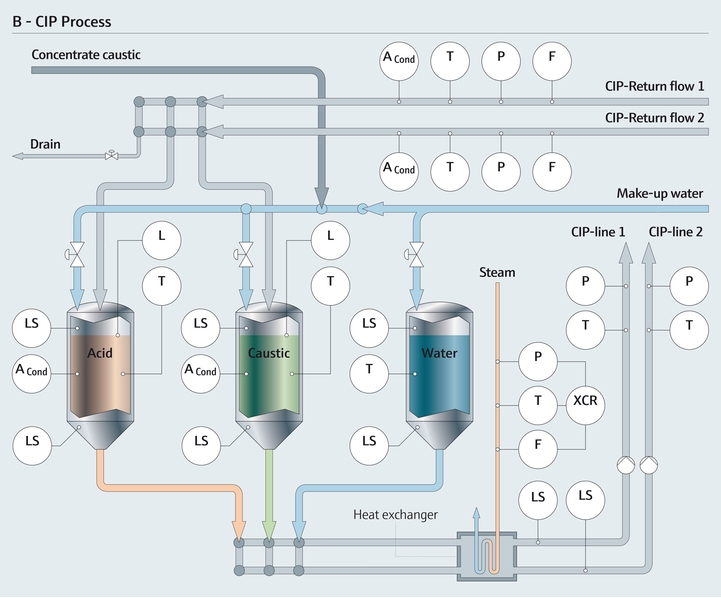

The major trend in food industry is the use of inline process measurements to control cleaning temperature, flow and detergent concentration. To truly optimize CIP systems and save valuable raw materials and energy, fast phase shifts in the return line are detected with optical systems. Concentration measurements are used to detect the degree of contamination of the liquids.

A CIP system requires large amounts of water, chemicals and energy. It is estimated that food and beverage plants spend approximately 15-20% of their time during the day on cleaning. Depending on the industry segment (dairy, brewery, etc.) and process, energy consumption varies. On average, a company uses about 10% of their energy in the CIP system. In addition, the average CIP process often consumes more than 15% of a company’s total water consumption to meet hygiene standards.

Food & Beverage producers often rely on a timed-based cleaning system. In view of the current resource shortage and rising costs, it is an ideal time to take a closer look at CIP system and implement optimization measures. Inline process measurements help food producers to switch from time-based to real-time monitoring systems. These systems ensure the highest cleaning efficiency, as well as reduced operational costs and losses.

Key facts

30%

savings on cleaning agent costs

by ensuring correct detergent strength and phase separation with Endress+Hauser's inline measurement portfolio.

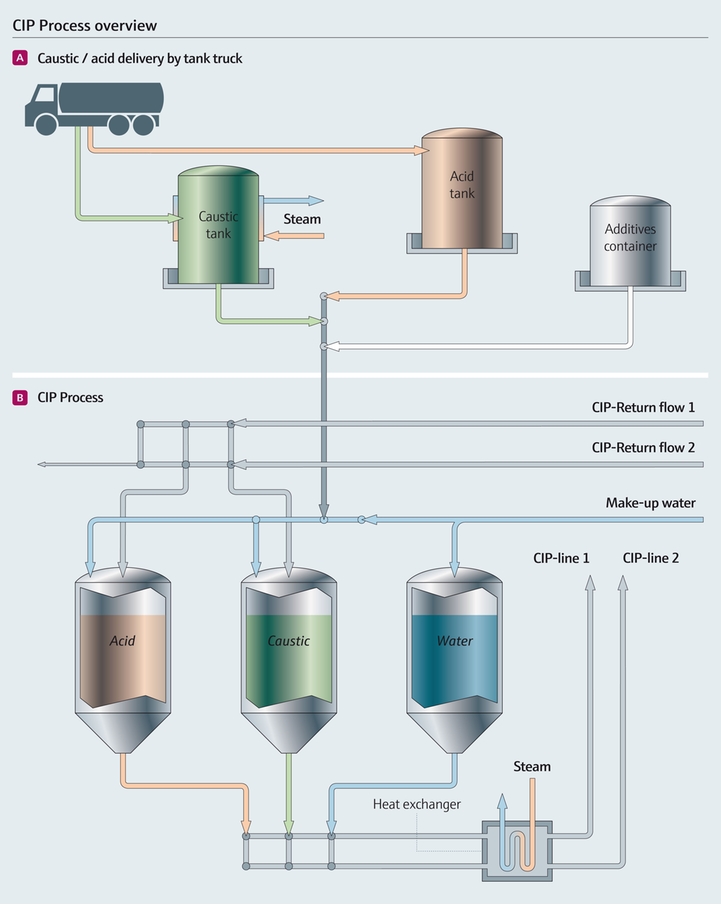

Your optimization potential in the cleaning process

Click through these process maps and learn in detail how you can optimize the entire cleaning process to reduce product loss and energy costs!

Optimize efficiency in phase separation

From guesswork to data-driven decisions. Know exactly what the line contains and remove any guesswork. Innovative transition sensors determine when each phase of a CIP cycle ends and when the next one should begin, resulting in product loss reduction and less risk of cross mixing of media. Optical instruments can be installed to better control phase separation. Rapid reaction time and real-time data provide savings by reducing water or chemical consumption and minimizing product loss.

Achieve a 30% cost savings by ensuring the correct dosage of detergents and efficient phase separation with Endress+Hauser optical measurements.

- Fast, safe and highly accurate inline phase detection and suspended solids with OUSAF11 absorption sensor. A faster separation prevents product wastage, ensures quality and safety.

- Compact and efficient toroidal conductivity system Smartec CLD18

- Accurate inline color and purity measurement with optical sensor OUSAF22

.jpg)

Precise temperature control

Temperature measurement is essential in the CIP cycle to ensure cleaning agents perform effectively, microbial risks are eliminated and hygiene standards are met. It protects equipment, maintains product quality, optimizes chemical usage and improves energy efficiency.

Benefit from error prevention and time savings with our hygiene modular thermometer iTHERM ModuLine TM411 temperature with QuickNeck - our patented thermometer extension neck with quick release for fast and easy recalibration - or our compact thermometer iTHERM CompactLine TM311.

Accurate concentration measurement

Concentration measurement in the CIP process is important to ensure cleaning agents are used at the correct strength for effective removal of residues and microorganisms, while also minimizing chemical waste, protecting equipment and meeting hygiene standards.

Our compact conductivity measurement devices Smartec CLD18 or Smartec CLD134 help you optimize concentration measurement.

Reliable flow measurement

Flow measurement is fundamental for an efficient CIP system. By ensuring a strong and turbulent flow, the desired scrubbing effect is reached.

The Proline Promag H 10 and Proline Promag H 100 flow meters are designed to handle the aggressive chemicals at elevated temperatures and higher than normal vibration due to turbulent flow. Endress+Hauser ensure performance for many years in CIP service. The flowmeters also include a temperature and conductivity output in addition to the flow value.

Build-up recognition ensure cleaning efficiency and avoid contamination

Cleaning efficiency is based on temperature, detergent concentration and flow velocity/shear forces at the installation walls. But as the pipes are not always straight and the reach of the spray balls is not always ideal, there are spots which are difficult to clean. To determine and improve the overall cleaning efficiency, it is necessary to also monitor the cleaning behavior at these spots. Furthermore, recognizing build-up early helps prevent microbial contamination.

Our compact point level devices Liquiphant FTL43 and Liquipoint FTW33 can detect process anomalies such as fouling or build-up. Installed in critical measuring points in the food processing plant, they reliably monitor fluid behavior and inform whether residual medium is present after cleaning. These innovative technologies allow the cleaning frequency and intensity to be tailored to the needs of a plant, thus increasing efficiency.

Safe level measurement

Level measurement is essential in the CIP process to ensure accurate control and monitoring of cleaning fluid volumes in tanks and pipelines. It helps to verify the use of the correct amount of cleaning agents, water and rinse solutions, thus preventing underfilling or overfilling that could compromise hygiene or waste resources. Reliable level measurement also supports automation, improves safety by preventing overflow or dry run conditions and ensures compliance with industry standards for cleanliness.

- Low/high level alarms and empty pipe detection (pump protection) are reliably monitored with our vibronic point level devices Liquiphant FTL51B or Liquiphant FTL43

- Monitor inventory safely with our non-contact radar sensor Micropilot FMR52